Anchoring is a subject that is often debated and analyzed, and yet much of what is being proselytized or disparaged does not adhere to fundamental principles of physics, human factors psychology, or a working understanding of rock quality and material science. It is not entirely mysterious how American climbers have gotten to this point, but it is certainly mysterious that so many of us insist upon remaining in a scientific and practical abyss.

Anchoring has evolved. It continues to evolve. If we want to continue that evolution, it’s valuable to explore the relationship between the past, the present, and the future. Today, anchoring is considered to be a precise, quantifiable art, but the science many climbers use to evaluate and quantify an anchor is dubious. Trusted and lauded concepts like equalization and no extension can be proven to be over-valued and/or inconsistently applied, which leaves us on uncertain footing.

If what we know about anchoring is questionable, what can we rely on? What does it mean when we say that anchors should be strong, secure, and simple?

HISTORY OF ANCHORING

The earliest written instructions for anchoring all emphasized the value of finding a reliable and unquestionable protection point. Rock horns, well-placed ironmongery, threaded holes and chockstones, and substantial vegetation all served to give a belayer enough security that his or her body belay would not be displaced by sudden dynamic loads. Importantly, climbers did not spend much time trying to quantify or calculate the properties of an anchor because the anchor was just one part of a system that depended largely on a gigantic human component: the belayer. Anchoring, as a skill set, was inextricable from the belay that relied on it.

This image, taken from The Climber's Bible by Robin Shaw circa 1983, typifies the instruction of anchoring in a previous era. The belayer uses his stance to guard the anchor.

Modern belay anchoring is much different. A belayer is not guarding the anchor with her own body weight or using the anchor simply to augment her stance. Instead, the anchor is expected to support a falling, resting, or lowering climber entirely, based on its own integrity and load-bearing capabilities. As a result, the anchor and its focal masterpoint have become the foundation of most technical systems for climbing rock and ice. For example, when top-roping, the anchor is usually asked to hold the belayer and the climber in a counterweight arrangement. In direct belays, the anchor and its masterpoint are asked to sustain the weight of the seconding climber and any loads created to assist the seconding climber. In multi-pitch climbing, the anchor is asked to belay the second and then sustain the upward pull of the leader.

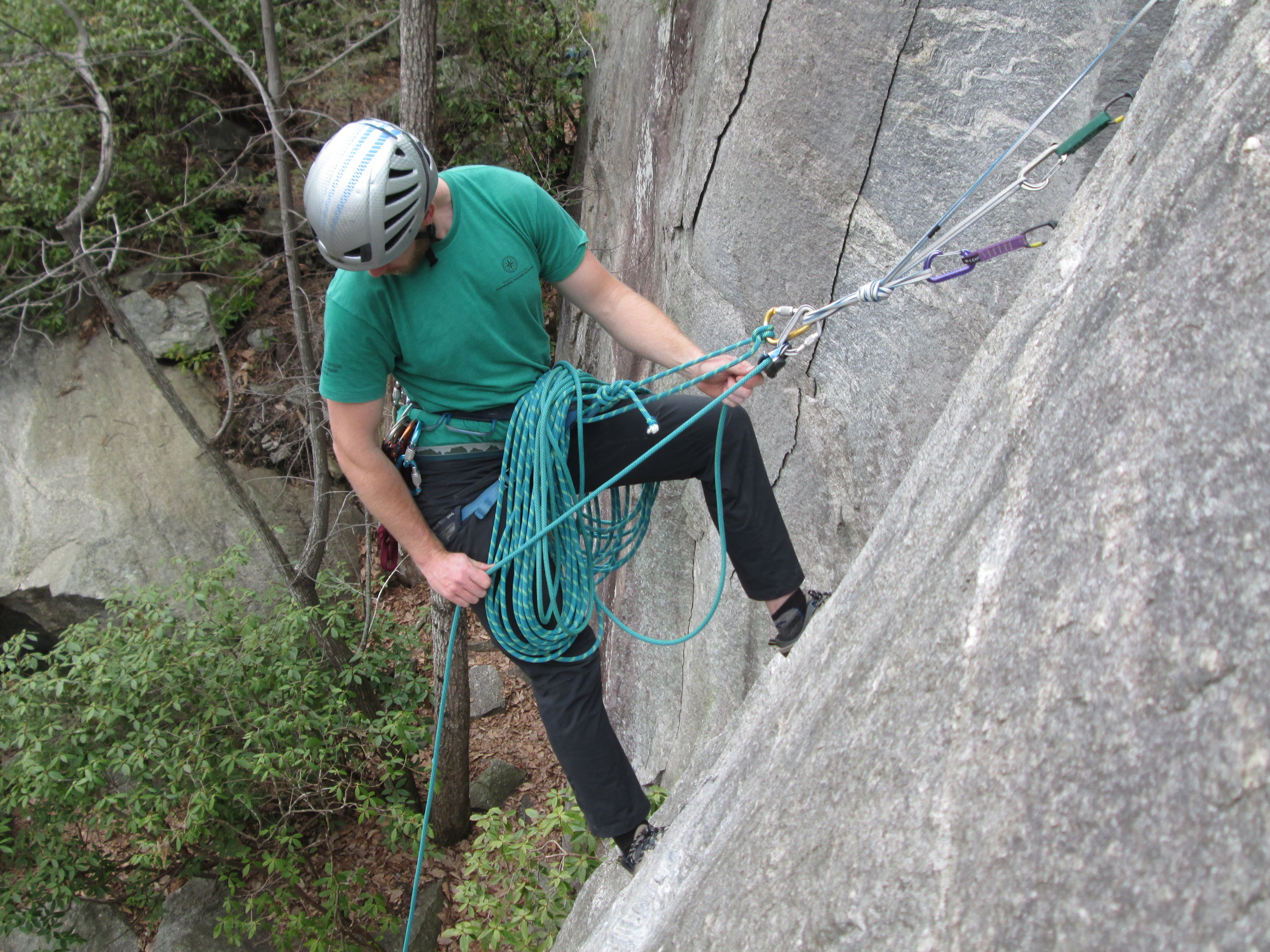

A modern belayer does not just use an anchor as a backup. As we can see, this belayer is fully committed to the load-bearing properties of the anchor. It holds his bodyweight, and the bodyweight of his second.

Whether we’re top-roping or multi-pitch climbing, whether we’re in the gym or at the crag, whether we’re building anchors with bolts or trad gear, we are increasingly dependent completely on anchors. And building them has become a foundational skill in technical climbing.

Belaying one or two seconds directly off the anchor is called a Direct Belay. If an anchor is reliable, direct belays are more versatile and more manageable than alternative configurations.

Modern anchors are configured to secure belayers no matter who they are belaying. They might be belaying a second; they might be belaying a leader.

ANCHORING PRINCIPLES AND ACRONYMS

A key aspect of modern anchors has been the development of acronyms used to teach and evaluate them. These acronyms are not without merit. They helped a generation of climbers inaugurate a new era in anchoring.

Anchor builders used such mnemonics like a checklist of key principles, and the anchors they created served climb after climb reliably and predictably. Here’s how a typical anchoring scenario might unfold: The anchor builder, armed with a fundamental principle like SERENE, arrives at a pair of bolts. She begins to work through her acronym. She assesses the bolts and feels they are both strong. Knowing she’ll need to build a redundant and equalized anchor, she selects a 7mm nylon cordelette as her attachment material. She doubles up the cord, clips one side to each bolt, targets the anticipated load, and then ties an overhand knot in such manner that creates two isolated legs and a masterpoint. She clips into the master- point with a locking carabiner and her clove-hitched climbing rope.

Before calling “off belay” she reviews her handiwork:

Good bolts. 25kN each, combining to 50kN at the masterpoint. Solid: Check.

One cordellette, one knot, 30 seconds to build. Efficient: Check.

If any single part of this anchor up to the masterpoint were to fail, there are backups. Redundant: Check.

When weighted, both legs of the anchor are tight. Equalized: Check.

If anything were to break, the masterpoint wouldn’t extend. No Extension: Check.

She’s built a SERENE anchor.

Anchoring acronyms help us ask basic questions about an anchor's qualities, but an absolute loyalty to concepts like redundancy and equalization can be misleading.

Millions of anchors have been constructed in approximately this fashion without incident or mishap, so it would be hasty to suggest that anchoring acronyms do not have value. However, climbers who also happen to be engineers, physicists, or just generally scientific-minded are quick to point out a fact that continues to elude a large number of climbers, climbing instructors, and authors of climbing books: Some of the qualities espoused in these beloved acronyms are not actually achieved in nature, neither practically, mathematically, nor experimentally.

Modern climbers have largely shifted from relying on the belayer’s weight as a key part of the system to relying wholly on the qualities of an anchor, and yet many of the qualities we aspire to achieve are based on nuanced falsehoods. As anchoring situations grow more complex, a climber attempting to tick every box on such an anchor checklist can waste significant time trying to reach unattainable goals. Worse, the climber may be lulled into a false sense of security.

The time has come, as a climbing culture, that we confront the modern science to ensure that it aligns with modern anchors. That might mean that many of our beloved acronyms are best suited to teaching novices, instead of remaining our only checklist as we grow in the sport. But it also might allow our understanding to evolve as rapidly as our sport does.

Anchoring acronyms still have value when climbers are first learning to build anchors.

THE MYTH OF EQUALIZATION

Anchors never really equalize. That is to say, they never manage to equally distribute the total load of the climbing team equally to all the components in the anchor, unless there is only one component. Yet, much false confidence and unnecessary time is contributed to achieving the elusive goal of equalization.

In experiment after experiment, the most carefully constructed anchor, with the most meticulous care taken to “equalize” all the components, will demonstrate that part of the anchor is holding most of the weight, most of the time. This is especially true if:

• The direction of the load alters in any way

• Any knots in the system tighten

• Any component fails

• The anchor builder intentionally ignores equalization in order to distribute more load to large components and less to small components

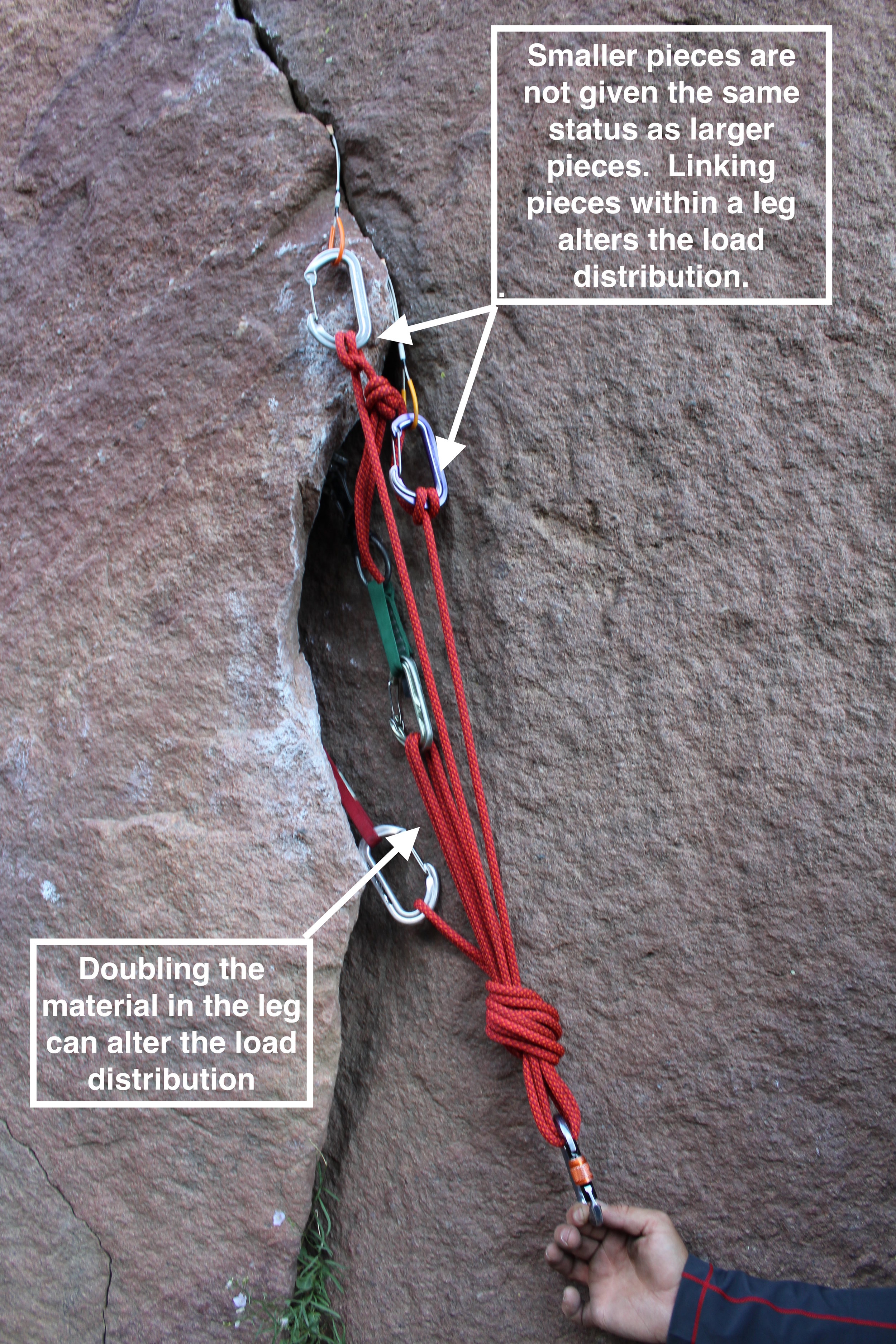

Even the theoretical load distribution of many anchors is not "equal." This anchor builder intentionally rigged to distribute more load to big pieces and less load to small pieces.

As a result, anchors that funnel into a masterpoint do not succeed, as intended, in aggregating the strength of the things they are attached to. A strong anchor thus is only as strong as the component that is holding most of the weight most of the time.

With an appreciation for this reality, many climbers gravitate toward “self-equalizing” anchoring systems. Magic X and quad configurations have become popular, but their ability to self-adjust to variable load direction is not perfect. The climber imagines that the shifting and sliding masterpoint allows equalization to happen, but in truth it only sort of happens...eventually...if the material doesn’t create too much friction. In the meantime, as the masterpoint slides along, the bulk of the load spikes from one component to the next.

What’s more, self-adjusting anchors all create opportunities for extension, despite the familiar anchoring acronyms’ insistence upon no extension. Anchor builders are forced to qualify that rule, applying load-limiting knots that limit or minimize extension.

For years, we’ve been loyal to principles that are scientifically inaccurate, encourage us to miscalculate the strength of our anchor, and force us to make convenient exceptions to principles like “no extension.” And while these acronyms enabled a generation of anchor builders to solve basic anchoring problems, in more complex scenarios these principles can easily become a liability.

WHY DO ANCHORS FAIL?

Indisputably, anchors fail because the load exceeds the force that the anchor can withstand. Theoretically, that should never happen because falling or lowering climbers create relatively small forces, given the capabilities of our equipment. So how does the load ever exceed the force an anchor can withstand? It happens in a few predictable and observable ways:

We use our equipment incorrectly. It doesn’t matter if the manufactured strength of a cam exceeds any load we could ever apply to it if we place the cam incorrectly. Similarly, a rope’s strength is irrelevant if we tie knots incorrectly.

Our equipment has been damaged. Chemicals or heat or trauma can cause imperceptible weaknesses in our equipment. We have to take good care of our gear.

The rock is not as good as we think it is. Evaluation of rock, ice, vegetation, and other anchoring media is a critical skill, on a micro and macro level. If there are hidden weaknesses, an anchor will expose them.

We just make mistakes sometimes. We can all appreciate that fatigue, haste, distraction, and peer pressure lead us to do uncharacteristic and dangerous things. It’s part of being human.

Acts of nature happen. There is such a thing as a no-win scenario in anchoring. We could do everything right and the mountain we’re climbing could collapse around us. That’s a bad day.

All this causality is actually good news. The list above is ordered according to factors that we have the most power and knowledge to prevent. We can learn to use our equipment correctly. We can take good care of our gear. We can evaluate the rock more carefully and more skeptically. We can learn to prevent most anchor failures by being careful and knowledgeable.

Such knowledge and care are part of what is keeping us safe out there, and if there are gaps in our knowledge, addressing the gap is vital. Instead of clinging to ideas like equalization and no extension, we can anticipate lurking dangers in our knowledge deficit.

FAILURE SCENARIOS

The following scenarios could be caused by a simplistic or inaccurate understanding of anchoring.

Small-component anchors. A devout loyalty to simple acronyms can have dangerous consequences when all the components in an anchor are smaller and weaker. If, for ex- ample, an anchor builder takes three small cams with 6kN of holding power each and imagines that an equalized masterpoint offers 18kN of combined strength, all the requirements of a SRENE anchor could be met. However, since equalization never really occurs, one of those pieces will be holding most of the weight most of the time. In that case, a single load that exceeds 6kN could sequentially rip every piece out of the rock, resulting in a catastrophic failure.

Lesson Learned: Avoid building anchors where no single component is strong enough to hold any potential load the climbing team could create.

Anchor builders start to imagine that they can aggregate the load-bearing properties of each component, which might not be true at all. One tiny piece is probably holding most of the weight most of the time, with only other tiny pieces as backups.

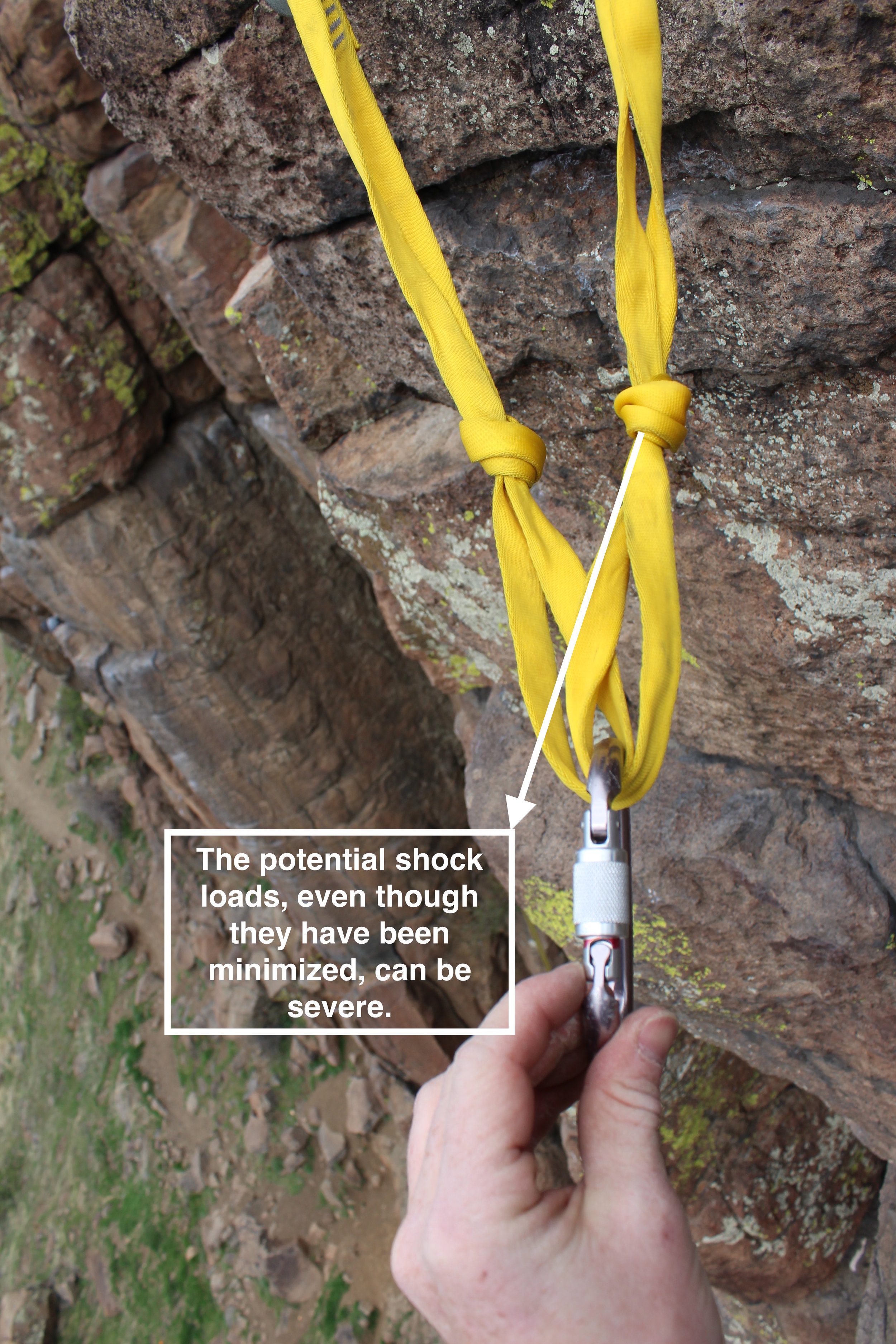

Adjustable anchors. Anchors that self-adjust, like quad and sliding X configurations, do not eliminate extension. Mathematical data suggest the potential shock loads created by extension (even limited and minimized extensions) can be severe. If an anchor is constructed with only two pieces of equipment, like two 10kN cams, all the requirements of a SRENE anchor could be met. Yet a load large enough to make a single piece fail could catastrophically shock-load the second piece as well.

Lesson Learned: If you’re using self-adjusting systems, make sure ALL the components can survive the expected loads AND potential shock loads. Bomber pieces are required.

Don't forget, adjustable systems do not necessarily create a perfect load distribution. Add a human factor or a large load and the resulting shock-loads can be more consequential than anchor-builders realize.

Stacked quads or Xs. Just as the self-adjusting properties of a single sliding X or quad configuration are imperfect, stacking these configurations multiplies those imperfections. The failure of a single piece proceeds to shock-load all the remaining pieces.

Lesson Learned: When stacking adjustable systems, make sure the components can handle expected loads AND potential shock loads.

All these potential extensions are also potential shock-loads. Can all the placements handle all those potential loads?

MORE COMPLEX ANCHORS

SERENE and EARNEST anchors are usually effective for simple top-rope anchors, but there are circumstances where an inability to escape that thinking could prove problematic. More complex anchors require more complex thinking and problem solving. These scenarios don’t occur that often, but, as climbers’ experience grows, most of us eventually will run into one or more of them:

The direction of load applied to an anchor changes. The belayer could lean on an anchor in one direction, the belay might tug the anchor in a different direction, and two climbers at an anchor might fidget and tug and lean in lots of directions. Belay transitions on multi-pitch climbs can offer dramatic direction of load changes too. Typically, the anchor is rigged to belay a second climber, and then the same anchor is used for the lead belayer. The two loads could be completely different.

All these different changes in the direction of load will shift the entire load onto a single component.

The components available for anchoring might be vastly dissimilar. Some cams are rated to hold over 14kN, while the smallest cams may be rated to hold less than 6kN. Even if equalization were achievable in an anchor, why would anyone expect these two cams to do equal work? They are not equally valuable components. When anchoring components have vastly dissimilar load-bearing properties, the rigging will have to be more complicated.

The concept of equalization presumes that each component is equally valuable. But, even perfect placements in perfect rock do not alway have equal load bearing properties, as pictured here. Anchor builders might instead make gestures to prioritize the strongest pieces, to equitably distribute load, rather than equalize.

A climber often has to construct an anchor with limited resources. The values and principles of anchoring do not change, but building a fundamentally sound anchor with limited resources is very challenging. It often requires some innovative and artistic problem-solving, hence the complexity.

How often has this happened to you? You've got to build an anchor with the gear you have left. It can get complicated when the resources are limited.

It should also be mentioned that the circumstances mentioned above might coincide and overlap. Since direct belays rely on fundamentally sound anchors, they may not be an option in some of these extreme scenarios. Belayers may need to insert their own bodies into the system, using stance to supplement the anchor, relying on the anchor as a backup only. Moreover, there is such a thing as a no-win scenario in climbing and in anchoring, when the available resources, the working skill set, or various dire circumstances will not allow an appropriate anchor to be built. When faced with this scenario, a tactical retreat, a call for assistance, or the aid of another climber is preferable to settling for anchors that may well result in catastrophic failure.

THE TRIPLE S: FUNDAMENTALS OF COMPLEX ANCHORS

When anchoring becomes more complicated, a more sophisticated approach positions the anchor builder to answer three basic questions:

Is the anchor strong enough?

Is the anchor secure enough?

Is the anchor as simple as it can be?

This is a broader, more inclusive way to think about anchors than the SERENE-style mnemonic. Call it the Triple S approach. Triple S anchors do not strive to equalize or to eliminate extensions; they strive to distribute load intelligently, minimize extensions, and avoid edge-case failure scenarios. Triple S anchors do not attempt to aggregate strength; they rely on unquestionably strong component parts and anticipate a human factor in that calculation. Triple S anchors do not muddle into unnecessary complexity; they solve the anchoring problem as efficiently as possible.

Strength. An anchor must be adequately strong to sustain all potential loads applied to it. Then, an anchor’s strength must be padded with a margin of error that could account for any number of mistakes that all humans are wont to make. Let’s be conservative and provide ourselves with a 100 percent margin of error. That would mean that any anchor should be strong enough to sustain all potential loads applied to it multiplied by two.

Security. This means that if anything unexpected happens—components fail, the direction of load changes—the anchor must survive those unexpected changes. An anchor that is secure has backups. It has systemic redundancy all the way to the masterpoint. If any single point in the anchor were to fail, other points would provide adequate backups. We make a few exceptions for anchors that are so titanic in nature (large, stable trees and boulders) that we might rely upon these single features alone, but even these features could be rigged in a redundant fashion.

Simplicity. A climber needs to appreciate that any anchor can quickly become convoluted and overly complex if it is rigged to solve phantom hazards or improb- able contingencies, or if it slavishly adheres to anchoring principles that are unachievable. For any given anchor, simplicity refers to the overall amount of time to construct and deconstruct an anchor. Simplicity refers to the overall amount of equipment needed, including rope, slings, carabiners, and any amount of padding or edge protection. All this should be minimized. Simplicity also refers to the number of knots being tied and untied, the number of steps needed to construct the anchor, and the distance the components are separated. All these should be minimized too.

When time, equipment, and number of steps are all minimized, and an anchor still demonstrates adequate strength and security, an anchor will have achieved the best end result our current knowledge and technology can offer.